Centrifugal compressors for the oxygen separation units.

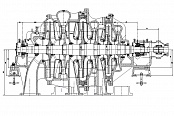

Compressor K3000-61-1

Design Features

Compressor K3000-61-1 is a double-cylinder, three-circuit, six-stage direct-drive machine with two intermediate coolers. The compressor is driven by the steam turbine with power output of 22 MW, which allow for the centrifugal compressor to change its operating mode due to a change of the rotor speed.

Compressor K1290-121-1

Purpose

The compressor is designed to compress atmospheric air at the low-concentrated nitric acid production line.

Design Features

The compressor is a double-cylinder twelve-stage (each cylinder has 6 impellers), four-circuit machine. After every circuit the air is cooled in the intermediate air cooler located outside the housing. The compressor is driven by a steam turbine K15-41-1 with power output of 15 MW, which allow to change the rotor speed within the range of 2500-3400 min.-¹. Rotor of the low pressure cylinder is driven directly by the steam turbine, and the rotor of the highpressure cylinder, via the speed increasing gear.

Compressor K1700-61-1

Purpose

The compressor is designed to compress atmospheric air, and to supply it to the oxygen units.

Design Features

The compressor is a six-stage, three-circuit machine. Each circuit consists of two compression stages. Air is cooled by the intermediate coolers located after the first and the second circuits. Air coolers are located in the basement room. To cool the compressor outlet air, a loop air cooler is provided. The compressor is driven by a synchronous motor STD-10000-2UHL4 (СТД-10000-2УХЛ4) with a power output of 10 MW.