Purpose

The compressor is designed to compress nitrous gas in the production of weak nitric acid.

The unit components:

- compressor with a built-in turboexpander;

- speed increaser;

- el. motor drive;

- electrical lubrication system;

- thermo-technical monitoring, control, protection and signaling system.

Design features

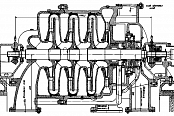

The compressor is a one-cylinder, four-staged machine with oneside suction.

The turbo-expander presents a two-staged impulse turbine and serves to reduce power consumption for compression of nitrous gas in the compressor. The turbo-expander utilizes the energy of waste gas in the production of weak nitric acid.

The compressor and turbo-expander components are made of special alloyed steels providing their corrosion resistance.

The compressor is driven by asynchronous electric motor 2AZMP-1600/6000 with a squirrel-cage rotor (rated at 1600 kW, 6000 V, 2980 rpm)/

The centrifugal compressor, having constant operating conditions, is not equipped with automatic governing facilities. The compressor capacity is maintained constant by varying the nitrous gases to make up air ratio.

The system of thermo-technical monitoring, control, protection and signaling consists of the board on which mounted are:

- facilities for the unit start and stop;

- instrumentation for remote measurement of the performance parameters of the centrifugal compressor;

- emergency and warning signaling devices;

- protection devices against the rotor axial displacement, against oil pressure drop in the lubrication system and gas pressure drop in the suction, as well as against higher temperatours in bearings of centrifugal compressor.