At the Nevsky plant, work on a large-scale modernization of the vacuum acceleration and balancing stand "Schenck" has been completed. The project was implemented jointly with Schenck, ABB and Neva technology LLC.

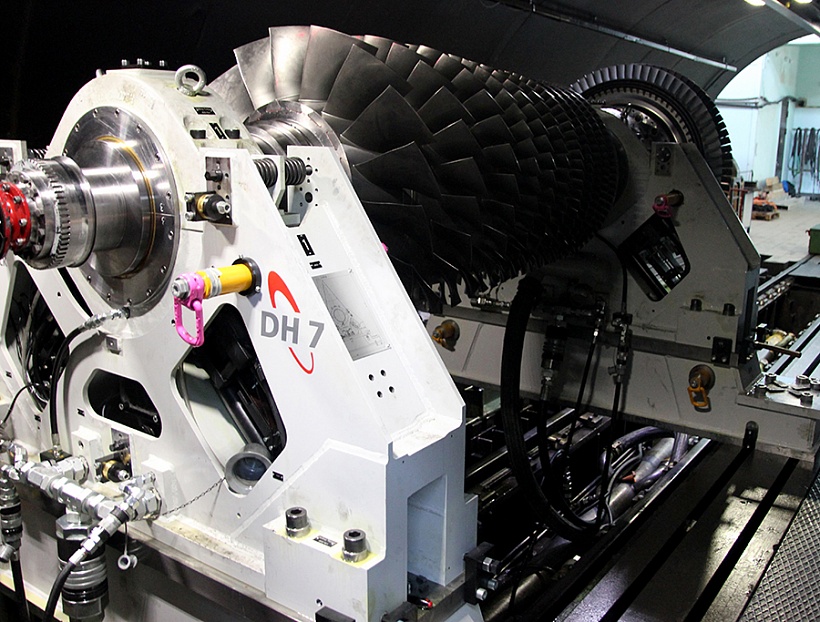

The acceleration and balancing stand is used for dynamic balancing and acceleration tests of rotors of gas turbines, steam turbines and compressors. It is equipped with a vacuum chamber, from which air is pumped out before starting balancing, and then the rotor is spun up to working speed.

"The turbine rotors are balanced when the rotors are fully ready, it remains only to make the last settings that will allow the rotor to work with minimal vibrations. This is a very important and responsible final operation, the quality of which depends on the operation of the entire unit, compressor station or entire power unit. The work of thousands of people who created the turbine or compressor depends on high - quality balancing, which is why so much attention is paid to this process," explains Mikhail Tyukhtyaev, Director of technological development of “REP Holding”, "it is impossible to spin such a rotor with blades in the air, so the rotors are balanced in a vacuum. Balancing specialists attentively monitor the behavior of the rotor and its vibration during balancing, and very carefully adjust its weight, gradually stabilizing its operation. Only then can the rotor be installed in the turbine or compressor."

During the complex modernization, the double-power drive was installed, the gearbox was replaced, the new high-precision intermediate shaft was installed, the racks on which the rotor was installed before balancing in the vacuum chamber were replaced. The oil pumps were replaced, and the new, more powerful transformer was installed. In addition, the most modern software Cabflex 3.0 developed by Schenck has been installed to support the balancing process and study the state of flexible rotors, the analog control and monitoring system was replaced by the digital. Amount of the investment for modernization was about 230 million rubles.

The implemented set of measures and new technical solutions allow to optimize the work of operators, significantly improve the quality of balancing and increase the reliability of the units as a whole. The upgraded stand allows high-speed vacuum balancing of rotors up to 10 meters in length and up to 2.8 meters in diameter, which makes it possible to localize high-power gas turbines in the future.

"There are only four such stands across the country", says Mikhail Tyukhtyaev, Director of technological development of “REP Holding”, “they are always extremely busy, and given the specifics of our rotors, not every company is ready to take up their balancing. That is why the stand-down period had to be reduced to a minimum. Due to the use of special technologies, the production of the foundation was reduced several times. Dismantling of the old equipment was completed just in a week. Employees of all departments of “REP Holding” and Nevsky Zavod, understanding the importance of this project, made every effort, experience and skill to speed up the process. As a result of these measures, we have a unique technical means and competencies that allow us to give our units unique consumer properties. This allowed us to move to a higher production level, and for our customers – this is an additional guarantee of the durability and reliability of our equipment."

The production work has already started at the updated stand, and up to the moment, the balancing of the gas turbine rotor for the gas pumping unit GPU-32 "Ladoga" was successfully completed.

Back to the news