As part of the localization program for components of the MS5002E gas turbine unit as part of the GPU-32 “Ladoga”, the certified batch of low-pressure turbine blade castings was manufactured. The project was implemented by specialists of the engineering center and the and technical development department of "REP holding" JSC in cooperation with the plant "Turbodetal"— a branch of "Gazenergoservice" JSC in Naro-Fominsk (the Moscow Region).

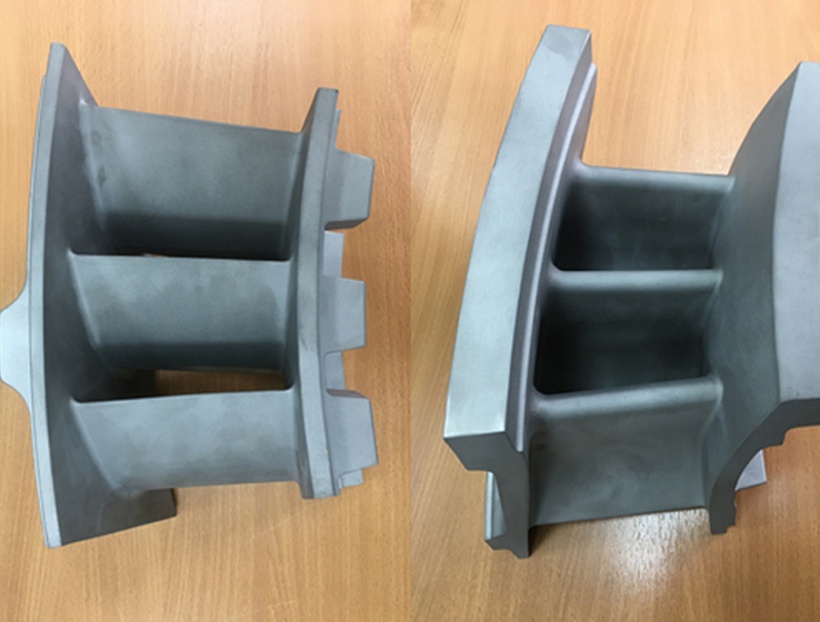

At the moment, the certified batches of working and guiding blades of a low-pressure turbine (LPT) have been manufactured, which ensure the operation of the compressor as part of a gas-pumping unit. LPT is one of the key components of a gas turbine unit, its efficiency and reliability directly depends on the well-coordinated operation of the blade system.

The working and guiding blades that form the blade system are among the most heat-loaded parts of the turbine, the surface temperature of the blade pen can reach 800⁰C, and the rotation speed - more than 5000ob / min, so they are made using advanced heat-resistant materials based on nickel and cobalt.

Currently, production of the first standard batch of low-pressure turbine blades using Russian castings has started – two sets of fully Russian-made blades will be manufactured by the end of 2020. Starting from 2021, the transition to the serial use of Russian-made blades will be implemented as part of the production of gas turbine units.

"Mastering the production of blades made of heat-resistant alloys is a key strategic goal of the program for localization of the gas turbine unit components," said Mr.Alexey Gorin, Vice President for development and production optimization, REP holding JSC. - The full cycle of blades manufacturing, starting from the selection of the supplier and pumping the transition to serial production, usually takes 3 years. At the moment, most of the difficult path has been passed, namely, the key stage is being completed — testing the casting technology and obtaining the necessary properties and characteristics according to the required technical documentation. The standard set of fully Russian-made blades will be manufactured by the end of this year. However, the results obtained now can already guarantee the possibility of manufacturing of the blades and guide vanes of LPT GTU MS5002E in the Russian Federation and, as a consequence, to increase the extent of turbine localization."

Back to the news