Power-Plant Engineering complex

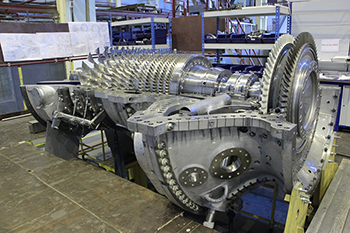

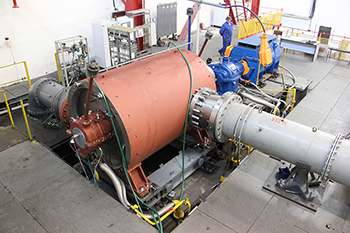

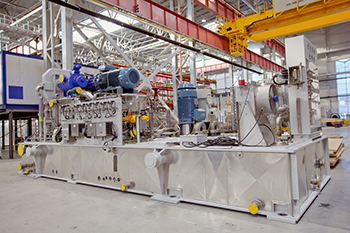

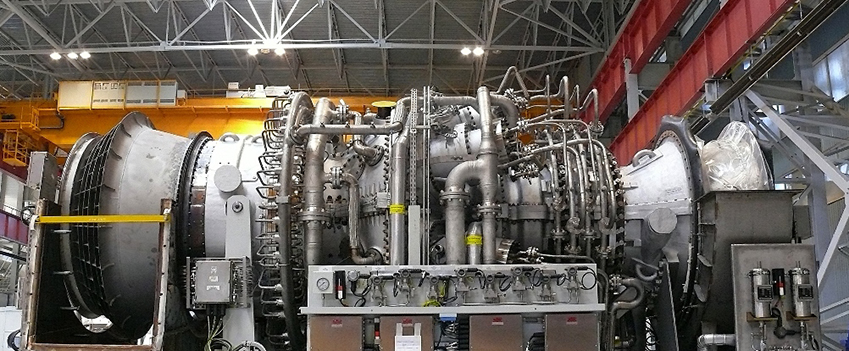

Its purpose is to manufacture steam and gas turbines, compressors and injectors.

Power-Plant Engineering complex consists of:

- Molding Site;

Produces sodium silicate and resin-coated (α-set process) molding and core sands by means of a batch-type screw mixer. Thus obtained sand mixtures are used for making of the cores and the molding boxes.

- Melting–and–casting area;

Capacity is 4300 tonnes of molten metal/year.

The modern DC melting units of WWOCCU-3 (wide-wave oven of constant current universal) and WWOCCU-0.5 series from “Ekta” company are used for melting.

It includes steel and iron melting, and, apart from that, produces high-strength iron which can be obtained by modifying (spheroidizing) the ladle content with a flux core wire (using wire feeding machine).

- Casting dressing area;

- Heat Treatment Site;

- Machining Site;

The site is purposed for rough machining of the castings and forgings. Also samples are cut-out for check of the metal chemical composition and mechanical properties.

The site is equipped with the threadcutting lathes, the vertical lathes, the horizontal boring machines, the rough-grinding machines, the vertical-milling machine and other machines for machining of the castings weighing upto 2.5 tonnes.

- Testing.

The products of the metallurgical section shall pass the following tests:

- ultrasonic testing;

- X-ray testing;

- magnetic particles testing;

- express-analysis of metal during melting process by means of the emission vacuum spectrometer ARL3460;

- check of the mechanical properties using metal samples.

Metallurgical segment is the most important element of the equipment production-packaged-sup¬ply cycle of “REP Holding”.

In 2010 the metallurgical segment was fully modified, the modern equipment, complying with the strictest requirements for production quality, safety, environmental safety and efficiency, was installed.

Metallurgical Section consists of:

Makes wooden patterns for items made of cast iron and steel. Also the site produces expanded polystyrene patterns.

It consists of:

- assembly–and welding:

- base–plates area;

- piping area;

- area for assembly of compressor wheels and cylinders;

- assembly–and welding area; - blank–and–mechanical production:

- gas cutting and forging area;

- mechanical area; - package production:

- packaging area;

- testing area;

- painting area;

- electrical equipment assembly, mounting and adjustment area;

- assembly–and–welding area.

Manufacturing of welded structures for various application in the power-plant engineering industry.

Boiler and Welding Section consists of: