Testing Center

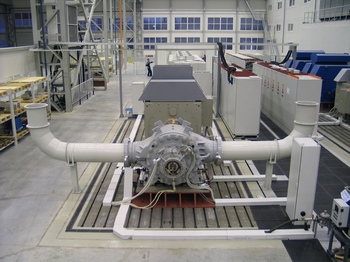

- Gas Turbine test bench;

- gas Turbine test bench;

- Centrifugal compressor test benches;

- test benches for axial compressors;

- vibration test bench;

- high–voltage testing;

- electric drive test bench;

- high–speed and low–speed bal¬ancing machines;

- EGPU test bench

- metering–metrological inspection (linear and angular measure-ments, radio metering, thermal measurements, metrological examination of documents);

- destructive tests (mechanical tests, metallographical tests, chemical and spectral analysis, etc.);

- non-destructive tests (NDT) (X-ray inspection, ultrasonic and penetrant inspection, etc.);

- the express–laboratory of the metallurgical complex performs express–control of metal during melting in the emission vacuum spectrometer ARL3460.

- spectrometer ARL 3460 Advantage;

- sample preparation machines Herzog VNU 300 and the grinding machine Herzog HT 350, express chemical analysis machines used during melting of steel and cast iron in the smelters;

- non-destructive test instrument Р920 Magnaflux for the magnetic particle testing of the rotor com-ponents and of the turbine and compressor casing castings;

- equipment of the company Zwick (Germany) for checking of the metal mechanical properties (strength and ductility) i.e. testing machine Z250 and impact testing machine RKP450.

The production sites of “REP Holding” are equipped with the unique high–tech test benches.

On these benches combined mechanical, thermal, and investigation testing of the manufactured turbocompressor equipment is carried out.

Test Benches:

Testing Laboratory

Assurance and control of the product quality is done by the spe¬cial department of CJSC “REPH”, i.e. the interplant metrology, test¬ing and quality control laboratory.

The laboratory does examination, and issues a report which is then submitted to the Quality Control Department inspectors so that they can decide further.

The laboratory does four types of inspection:

The laboratory is equipped with the modern equipment from the leading foreign manufacturers:

The laboratory carries out a wide variety of tests, e.g. X-ray testing, chemical analysis, spectral analy¬sis, magnetic powder test, ultra¬sonic test, etc.