Nevsky Plant and Plant “Electropult” summed up the intermediate results of their participation in the National Project “Labor Productivity and Employment Support”. The participation in the national project intends the implementation of the tools for lean manufacturing at the enterprise. 15 manufacturing companies participate in this program in Saint Petersburg. As follows from the analysis of the manufacturing activity of enterprises, the areas, requiring, the improvement are found out, the analysis of the main types of non-production operations is performed.

The purpose of the Nevsky Plant and Plant “Elektropult” participation in the project was the necessity to increase the labor productivity due to a significant increasing of the order portfolio and growth of the production volumes.

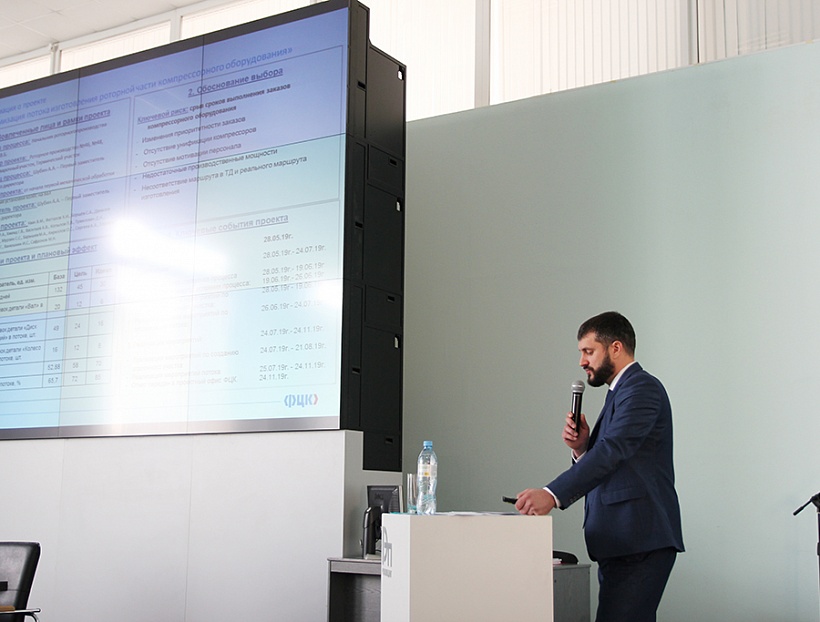

At Nevsky Plant, the rotary production was chosen as the pilot area for working in cooperation with experts from the State Competence Center in the field of labor productivity, because the manufacturing of the rotor part of the compressor is the most responsible, and the highest requirements are imposed on it in terms of quality and accuracy. At the Plant Electropult, the pilot area was the manufacturing of modular containers «2БКТП – 1000/6/0,4».

During diagnosis and visualizing of the problems, the main types of flow losses were identified: the overproduction, the excess stocks, the long-distance transportation, the excessive processing. For example, the inter-workshop movement of wheels at the Nevsky Plant during the manufacturing of rotors after the implementation of the national project is planned to be cut to a third. Except that, the quantity of the work-in-process pieces at site was already halved, which significantly accelerated the manufacturing process of the rotor part of the compressor from 132 up to 80 days.

Because of the measures taken at the Plant Electropult, it was possible to reduce the area of temporary storage (up to 30%), the time of tools searching (up to 80%) and the time of production processes (up to 75%).

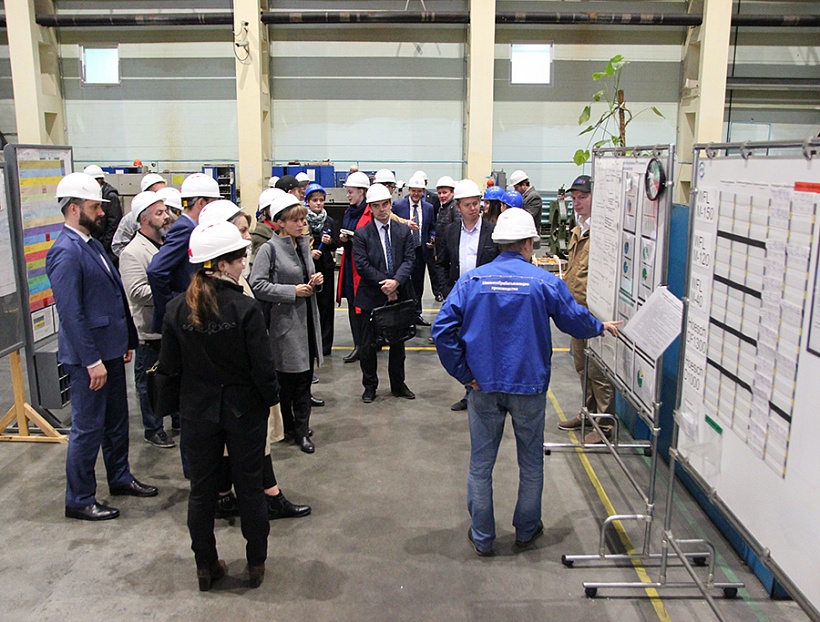

The application of the management system and work place simplification 5C, the development of the spaghetti chart, which describes the movement trajectory of workers, vehicles, tools around the enterprise, the visualization of the problems, the creation of the information center, where the brief meetings are held daily to assess the situation, in complex, helped not only reduce costs, but also to involve the staff members in the process of production lines developing.

According to experts of the State Competence Center, the main factor of the successful implementation of lean technologies and increasing of the productivity - is the involvement and interest of company employees, as well as the indifferent attitude of the management. This is the only way to create at the enterprise the culture of continuous improvement, which is the only priority to increasing productivity.

“Because of the implemented improvements even in this year, the company will be able to increase the efficiency of key equipment up to 5-7%,” Mr. Igor Mishin mentioned, the Director General of Close Company “Nevsky Zavod”. – The participation in the National Project has become a useful external stimulus for the Nevsky Plant, which allowed us to review routine operations and identify the reserves for growth.”

“We learn more successfully to manage the production process, increase the efficiency of use of production facilities, and in the future we expect to increase the throughput of the enterprise. We plan to increase productive capacity up to 20% by 2022”, says Regina Portnova, the Director of Economics and Production Planning of JSC “Plant Electropult”.

According to the Chairman of the Committee on Labor and Employment of the Population in Saint Petersburg Mr. Dmitry Cherneyko, for the development of the country's economy as a whole, it is necessary to make the work of professionals at the manufacturing sites more efficient. “We have been working with REP Holding companies for more than 5 years. And during all this time we are engaged in a key task - the advanced retraining of personnel. Investing in people, we change the quality of human capital at the city enterprises and solving the problem of staffing for economic development. ”

Since this year, the Committee on Labor and Employment of the Population in Saint Petersburg implements two regional projects. “Targeted support for increasing labor productivity at enterprises” is aimed to the implementation of lean manufacturing technologies and forming the culture of continuous improvement in enterprises. By participating in the project “Supporting Employment and Improving the Efficiency of the Labor Market to Ensure the Growth of Labor Productivity”, the companies will be able to improve the skills of their employees or even give them a new profession.

“Regional projects are critically important; because they help enterprises maintain their competitiveness. High labor productivity is, first of all, the company's security in the future. All the leading economies of the world rely on lean manufacturing and here we cannot afford to lag behind,” emphasized Mr. Vladimir Solodov, the Deputy of Director General of the State Competence Center.

The key goal of the national project is to accelerate the growth of labor productivity up to 5% per year by 2024 compared to 1,4% in 2018 at medium and large enterprises of the basic non-primary sectors of the economy.

Mr. Alexei Yakovlev, the Deputy of Chairman of the Committee on Industrial Policy, Innovation and Trade of Saint Petersburg, emphasized that the Committee’s task is to attract more than 800 enterprises to participate in the National project “Labor productivity and employment support”. The participants of the National Project “Labor Productivity and Employment Support” receive priority rights to loans at a rate of 1% per year from Industrial Development Fund of RF, opportunities for participation in the export accelerator of “Russian Export Center” and a lot of other preferences.