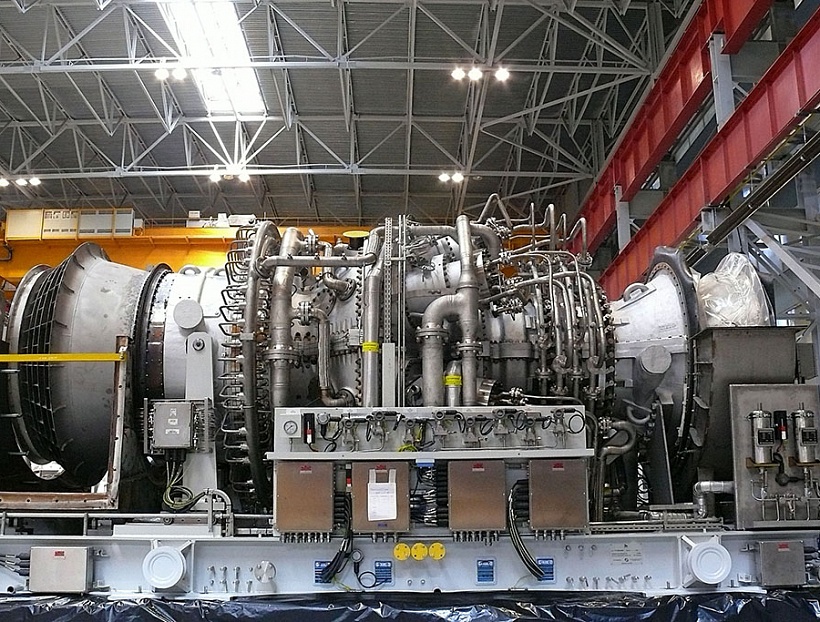

REP Holding has mastered the production of the most technological and high-tech parts and components of MS5002E GTU which is part of the new generation gas-pumping unit «Ladoga-32».

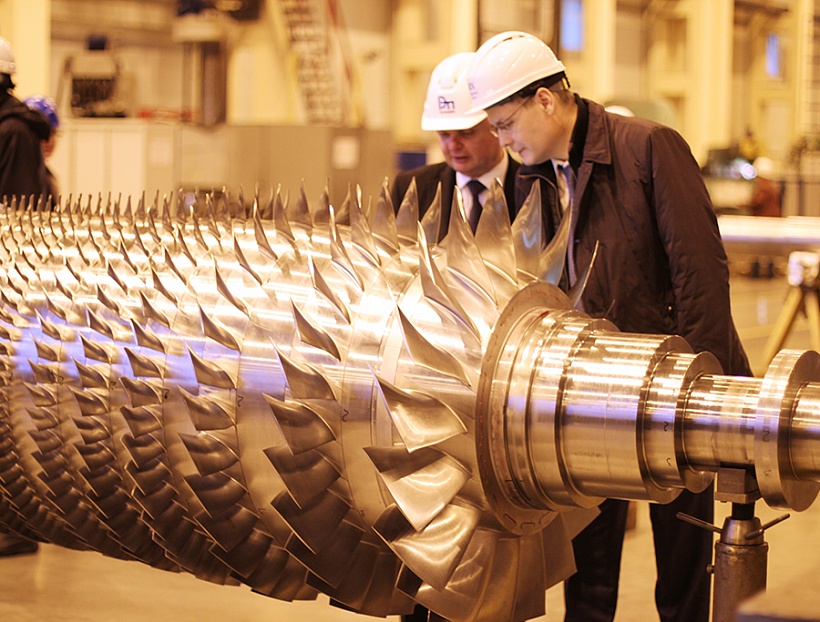

As part of the localization program, which is systematically implemented at the Holding facilities, the prototype of the rotor of the high pressure turbine axial compressor and the whole set of compressor blades have been manufactured. Manufacture of turbine blades and the combustion chamber elements is at the final stage.

Also, within the frames of this project REP Holding specialists have independently developed and manufactured a set of GTU bearings, using Russian materials grades, which will make it possible to avoid using the foreign manufactured analogues.

The project has been implemented in close cooperation with domestic enterprises within record-short time. Having started in February 2017, REP Holding mastered the production of the high-tech components of the gas turbine actually within 1 year. To complete the project, more than 20 collaborators, Russian industrial companies, were involved.

The tests performed at the premises of NPO TsKTI, one of the leading Russian power engineering institutes, confirmed the quality of materials and machining processes.

Long-cycle full-scale tests of the localized parts will be carried out on one of the gas-pumping units manufactured by REP Holding at the booster compressor station «Vavozhskaya» of the main gas pipeline «Yamburg -Tula 1». Installation of the localized parts and components is synchronized with the repair and maintenance program of PJSC «Gazprom». All maintenance and installation of localized units is scheduled to be completed by April 1.

The deeper localization of production became possible by the agreements reached with GE about transfer of the full set of documentation, including the hot part of the turbine. The relevant agreement with GE Oil & Gas was signed at the end of 2014.

«Receiving the full set of technical documentation, including the hot part for an industrial gas turbine, is an unprecedented deal that gave us the opportunity to offer a competitive product for the market without foreign participation», Alexey Gorin, JSC «REP Holding» Vice-President for production optimization and development said, «The project is essentially unique, because there was no experience of localizing the hot part of industrial gas turbines in our country as yet. In the near future we plan to complete the localization of the combustion chamber, as well as auxiliary equipment control systems: the fuel valve automatic control system, vibration system and pulsation control system. The production localization solves very important tasks. First, it will make it possible to reduce the cost of manufacture and service maintenance of the GTU. Second, the work on localizing develops our engineering capabilities: the key personnel of the gas turbine equipment designers and technologists is formed, noninferior in their skill level to our foreign partners».

5 March 2018

REP Holding has Completed the Important Stage in Production Localization of MS5002E GTU